About the Show

Plastindia series of exhibitions under the aegis of Plastindia Foundation stays as a permanent date in corporate calendars across the world, providing investors and industrialists with a compelling doorway to global markets of commerce and success. 10 exhibitions old, today, Plastindia has grown into a global experience, covering the entire gamut of plastics producers, processors and users of plastics, and it witnesses intense participation by both Indian and International Plastics Fraternity. The Plastindia editions have transformed marketing opportunities into convincing sales potential, and have empowered businesses, big and small, with the stamina to compete during tough economic times.

The Back Flush Reports, the Material requirement Planning , The Cavities, Moulds, Family Moulds, the PPM, the OEE, the Tool Change Time and so on are the part of our ERP Trajectory.

Plastic Moulding ERP Software Finsys

Stage to follow in Production Module

for Plastic Moulding Industry : Model 1

- Create “Bill of material” for finished goods and Semi finished which is link in FGS ( Finished Goods Stores)

- Machine sections :- like (moulding, painting, assembly)

- Mould master (for mould life)

- Machine master (link item with mould, cavity and shot/hour)

- Down time reason section wise

- Rejection reason section wise

- WIP stages which we follow in production routine

- Production user raise a work order of moulding item for production

- Automatically material requirement planning is generated for that work order

- Store user will make a store issue against this work order

- Store issued material is shown in WIP stock

- Moulding production entry of FG item (if is only saved if there is stock in WIP)

- QC = In process QC Inspection of that FG item for WIP stock

- WIP stock is generated in moulding stage

- In case this item is Directly “Mould” to “sold

- FGS stock is generated in PDI

- Production finish entry for stock generation

Plastic Moulding ERP Software Finsys

From injection and extrusion moulding to thermoforming, Finsys ERP Software can address the needs of your business. It is a fully integrated manufacturing management, accounting, Production, PPC, and customer relationship management all in one system.

Features and Benefits of Finsys ERP

The ERP System made for Indian Conditions. ERP Made by Chartered Accountants, and Plastic Engineers, keeping in mind the needs of SME’s. Best of Both Worlds, Easy and Strong. As Easy as an Accounting Package, with Drill Down, As easy as Google to Search, and as easy as the most Robust ERP of the Word.

Time to Train ? single day for single user for single module. Yes, it can work ( Conditions apply , and that is just simple positive minded approach, and will to learn ). !

Traceability and Tracking

All goods received can be booked in using a unique MRR coding system. For all finished products, components and raw material involved can all be traced from initial purchase to dispatch. Finsys even has a Bar Code / QR Code system , which can be integrated from the Input Material to the Master Batch, to the Work in progress, to the Finished goods, and upto the shipment.

Materials Consumption Monitoring

Use Finsys ERP to reconcile the weight difference between the input of raw materials and the subsequent component production, Lumps, RR ( Runners and Risers) and re-grindable or saleable scrap polymer. This allows managers to proactively monitor scrap levels, set realistic targets and highlight areas where processes need to be improved.

Production Scheduling

Using, Finsys ERP, your Planners can use the production scheduler to manage multi-cavity tooling, work schedules, labour, setup times and group work orders with ease. Planners will be able to see bottle-necks, create activity centres for specific jobs or tooling method and see available capacity at any given time.

Documentation Storage

Business documentation from manufacturing, tooling specifications and product configurations to packaging requirements, can all be securely stored in Finsys ERP. All communication with external stakeholders can be stored within the integrated CRM feature. This includes emails, faxes, bills of material, sales orders, purchase orders and customer or supplier specifics.

Tooling Controls

Finsys ERP can assist Production Managers with multi-tool management including processes such as blanking-off, enabling the production of multiple product ranges at the same time. The tools lifecycle can be tracked within the system, purchase dates, services and decommissions can all be logged.

Sales Order Processing & Automation

Both Sales Order system and Sales Schedule System are incorporated. All parts and materials costs can be programmed into the ERP system so gross margins can be immediately calculated once a quote is created. EDI processes such as order confirmations, invoices and delivery notes can be automated and sent electronically to the recipient, saving time and resources.

Plastic Moulding ERP Software Finsys

Grouping and Subgrouping in Finsys ERP, suggested Users Manual

Mobile Phone based, QR Bar code Based issue of Material : Same technology as shown in the YouTube Video Below

Mobile Phone based, DATA ENTRY of Finished Goods and QR Bar code Based INVOICING of Finished Goods.

Application of this innovative Technique and Technology for Plastic Moulded Components, as shown in the YouTube Video Below

Mobile Phone based, APPROVAL OF PO, AND STORES ISSUE of RAW MATERIAL AND BOP

Application of this innovative Technique and Technology for Plastic Moulded Components, and Rubber Moulded Components, as shown in the YouTube Video Below

INTEGRATED ERP SOFTWARE FOR PLASTIC INJECTION MOULDING

The particular properties of the material that is plastic and the almost limitless possibilities afforded by the various processes for injection moulding plastic make the injection moulding industry one of the most interesting and diverse industry sectors of all.

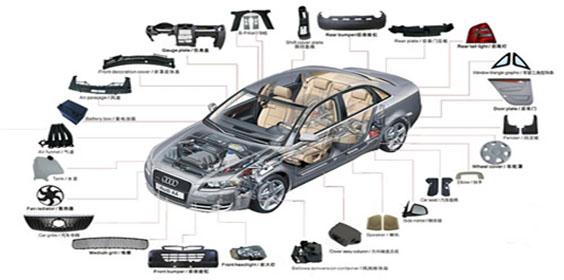

Customers in almost all industries, in particular the packaging industry and the automotive sector, but also telecommunications, electronics, medical engineering and mechanical engineering, use products from the injection moulding industry.

The offering is wide and varied yet success will only come to those injection moulders who have full control over quality, innovation, delivery reliability and costs. Progressive digitalisation in all areas of life both drives these challenges and is the key to your solution: It accelerates business processes, revolutionises market activities and unleashes an as yet unimaginable number of creative possibilities.

State-of-the-art software technology for your digital business

For quite some time, modern business processes have been supported by an abundance of digital tools: From telecommunications, daily office processes, financial management, customer relations, warehouse management and logistics through to strategic business decisions, there is no area left that does not benefit from highly specialised software solutions. It is essential that all these solutions are optimally aligned to work in concert, creating added value through the intelligent provision and processing of information. FINSYS provides intelligent software solutions to digitally support all aspects of your business. Our ERP solutions for plastic injection moulding are based on state-of-the-art technology from Microsoft.

Your complete solution for plastic injection moulding

The plastic injection moulding industry manufactures a wide range of products for a variety of purposes, and the production processes that come into play here are equally varied — as are the requirements placed on the software infrastructure.

FINSYS ERP offers an extensive portfolio of fully integrated industry and specialised ERP software solutions for companies in the plastic injection moulding industry.

These solutions support all industry-specific production processes from scheduling and capacity planning, optimising maintenance and setup jobs, through to detailed batch tracking, and integrate these processes in the commercial, sales and strategic business workflow. Our quality management supports you in your daily quality assurance and in the optimisation of your supplier relationships. Mobile storage management allows logistics processes to be directly networked with the business logic of your enterprise solution. And our automotive solution also enables you to map the special requirements of your customers and suppliers in the automotive industry.