Questions we have answered here are

-

How to do ERP implementation in a Corrugation Plant ?

-

How to do implement Barcode based Reel management in Finsys ERP

-

How to be successful in the ERP implementation in Corrugation Packaging, Duplex Packaging, Flexible Packaging and Label Packaging

Steps for Corrugated box industry, all Industries, anybody who wants to consider barcoding in his factory

For Benefits, already seen – see the Youtube on that topic.

It is NOT Difficult

There is negligible cost and no Loss

Steps of doing / implementing

- Traditional way

- Spiral Way

Traditional way ?

- one time prepare

- one time go live

Spiral way ?

- Do Step by Step

- 7 Activities parallely , or one by one

- Dont worry

- Start

- we spiral upwards

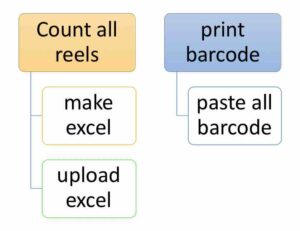

Traditional way – part 1

- Count all reels

- make excel

- upload excel

- print barcode

- paste all barcode

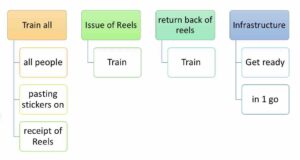

- Train all

- all people

- pasting stickers on

- receipt of Reels

- Issue of Reels

- Train

- return back of reels

- Train

- Infrastructure

- Get ready

- All in 1 go

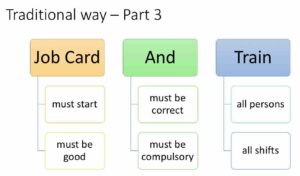

- Job Card

- must start

- must be good

- And

- must be correct

- must be compulsory

- Train

- all persons

- all shifts

but all this is very difficult in 1 go